AISC 360-10 and AISC 360-16 Steel Member Design Software

This documentation applies to AISC 360-10 (14th Edition) or AISC 360-16 (15th Edition) in either ASD or LRFD provision.

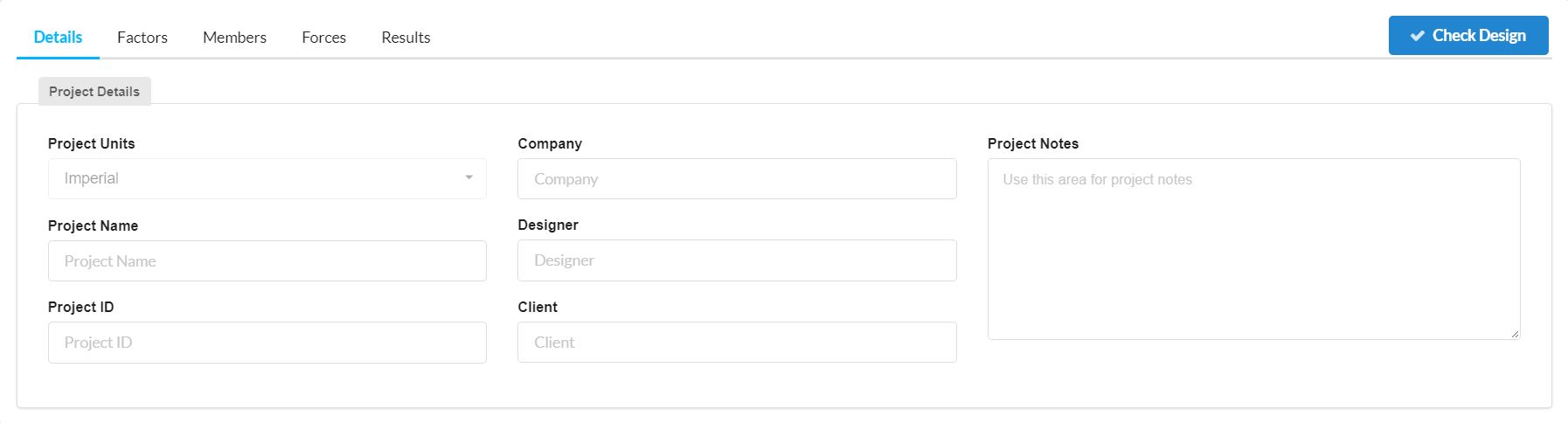

- A Project Name;

- A Project ID;

- Your Company Name;

- The Designer;

- The Client; and

- Any other notes you would like to include

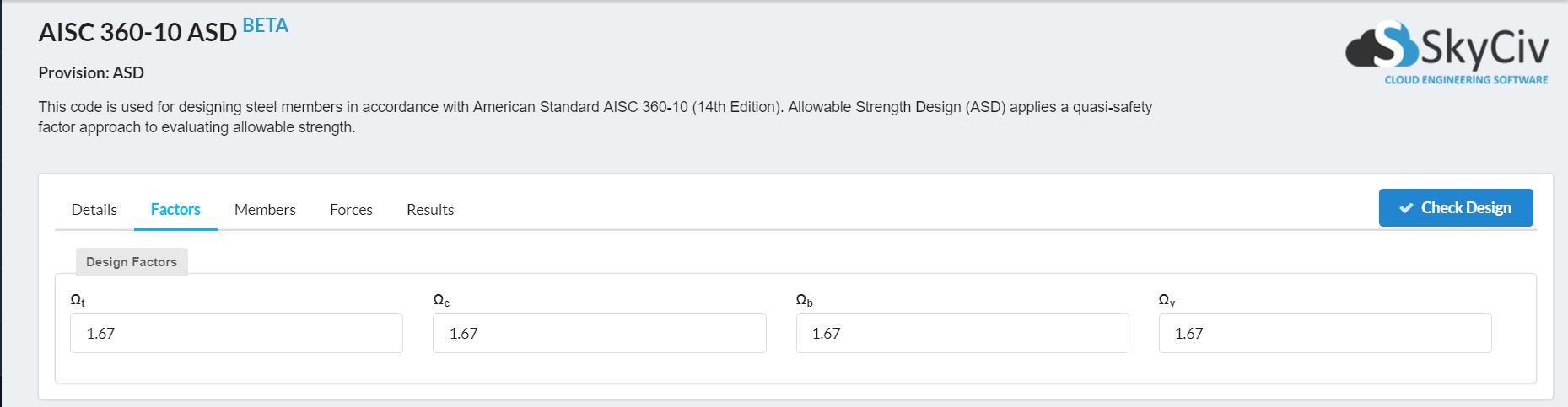

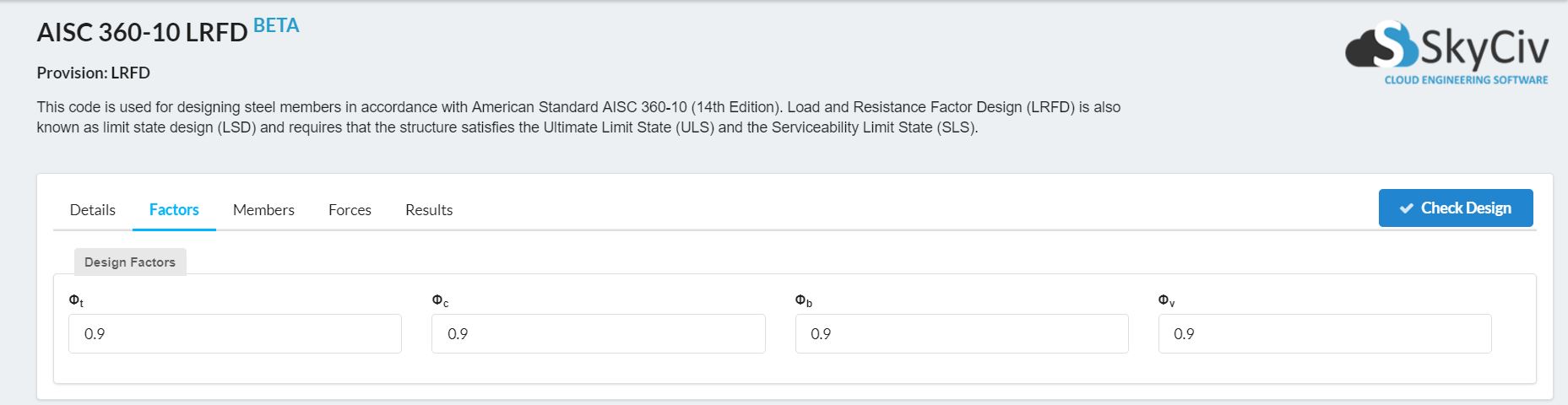

Factors

Both ASD and LRFD are used for designing steel members in accordance with American Standard AISC 360. However the Allowable Strength Design (ASD) design software applies a quasi-safety factor approach to evaluating allowable strength. Whereas Load and Resistance Factor Design (LRFD) is also known as limit state design (LSD) and requires that the structure satisfies the Ultimate Limit State (ULS) and the Serviceability Limit State (SLS).

The main difference you will notice is in the Factors tab as shown in the figure below for ASD and LRFD respectively.

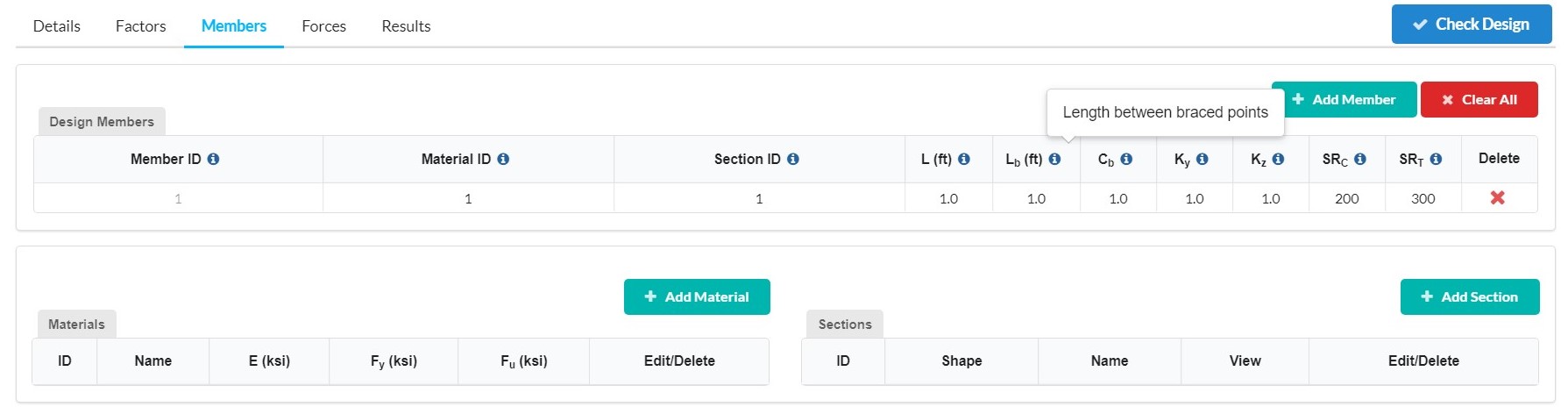

Members

The Members tab is where you can define any members that you are working with by clicking the + Add Member button.

Each Member you add must include a Member ID, a Material ID and a Section ID as well as an array of factors shown in the image below.

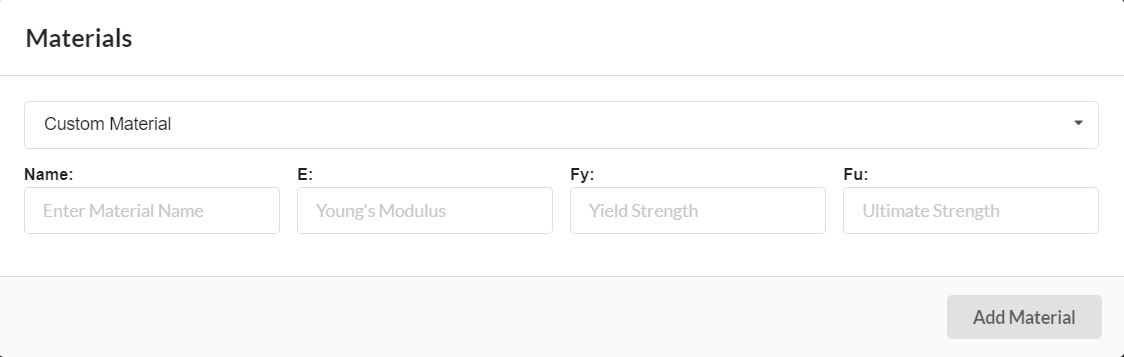

Once you have added your members in you need to specify what materials you are going to be using. This is done by clicking the + Add Material button which will open up the following menu.

- Structural Steel;

- Aluminium;

- Carbon Fibre Reinforced Plastic;

- Concrete;

- Concrete High Strength;

- Oakwood; and

- Glass.

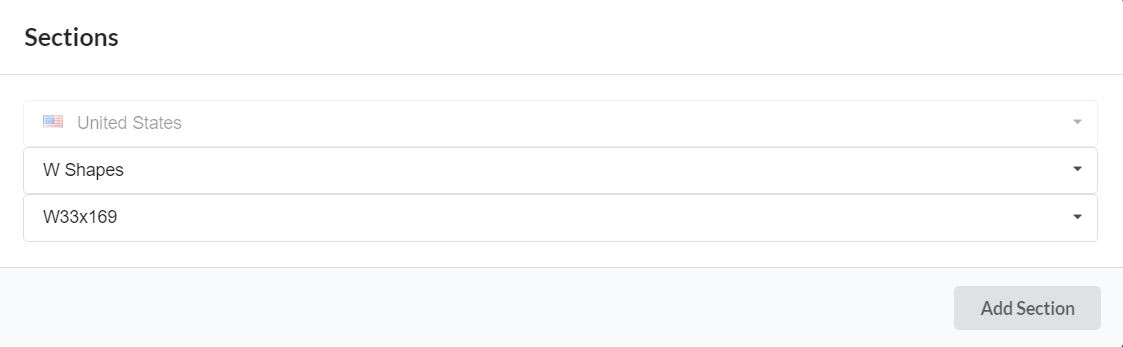

Once you have added your materials in you need to specify what sections you are going to be using. This is done by clicking the + Add Sections button which will open up the following menu.

- Rectangular HSS;

- Round HSS;

- Square HSS;

- American Standard Channels;

- Column Tees;

- Equal Angles;

- HP Shapes;

- M Shapes;

- Miscellaneous Channels;

- MT Shapes;

- Pipes (obsolete);

- Rectangluar Tubes (obsolete);

- Square Tubes (obsolete);

- S Shapes;

- ST Shapes;

- Unequal Angles;

- W Shapes;

- WT Shapes; and

- Double Angle.

After which you can go on to choose the exact section you would like from the extensive lists included.

Forces

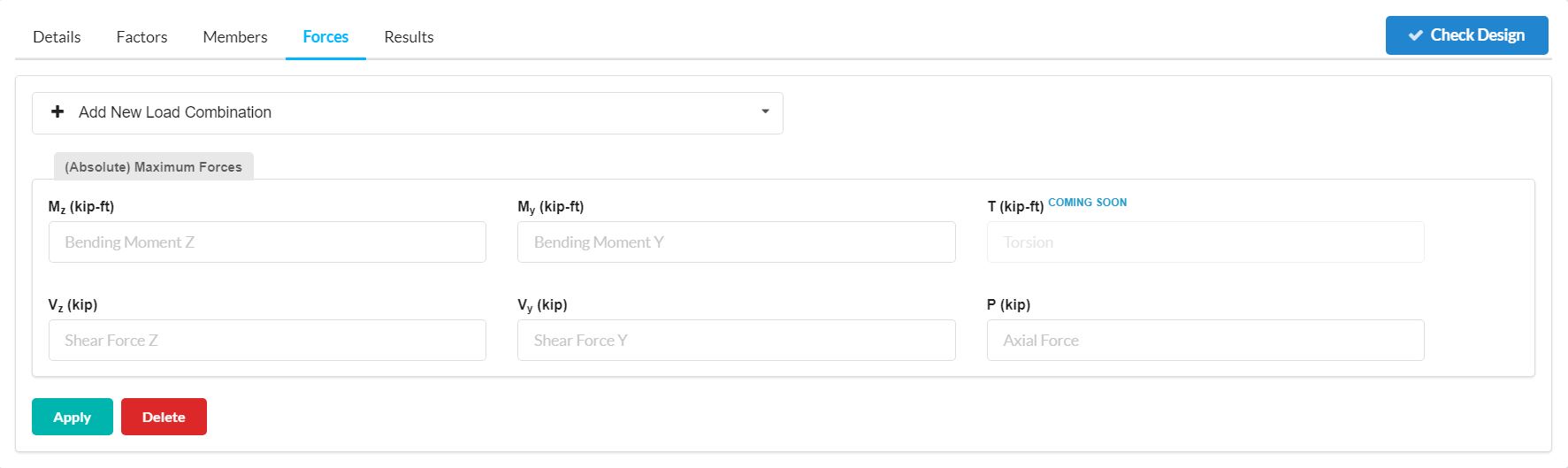

The Forces tab is where you can define any forces that are applied to your members by entering in the relevant forces and then clicking the Apply button.

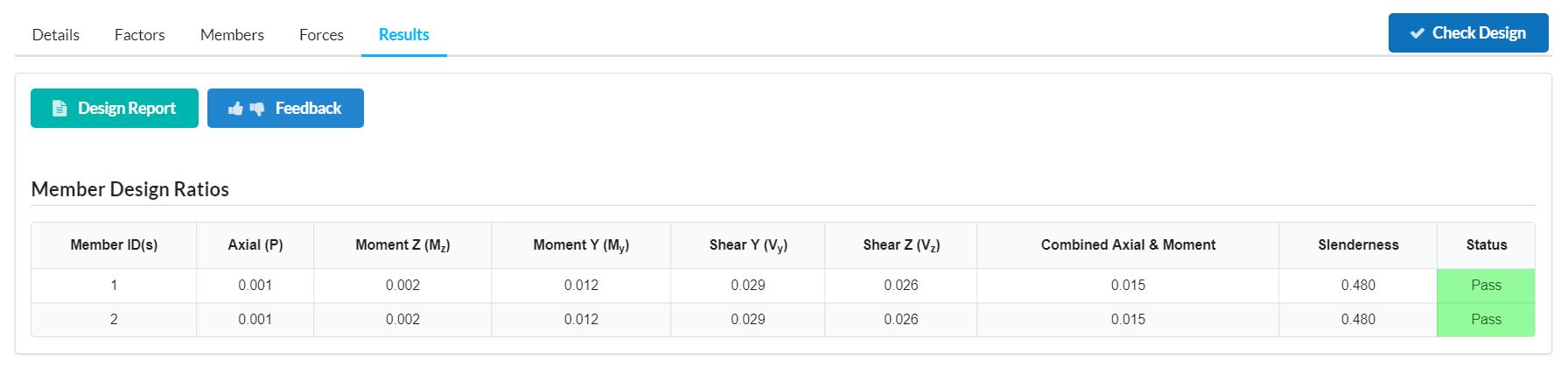

Once you have designated your Details, Factors, Members and Forces click the Check Design button shown in the figure above to run the design check which will then mean you can check the Results tab as shown in the figure below.

Limitations in the AISC 360-10 and AISC 360-16 Modules

- The hot-rolled members considered in the design are I-shapes, C channels, HSS rectangular and circular tubes, T sections and angle sections. Other sections like double channels, doubles angles, I-sections with different flanges or built-up sections are not considered.

- For combined bending and tension (Section H1.2) the code allows a modification of the Cb factor. This is not considered in the program.

- Only tensile yielding is considered for tension forces due to insufficient information related to steel connections in member design.

- The program just considers the worst strength in relation to positive or negative bending. This affects sections with asymmetries like sections T and L.

- Torsion is not considered in the design. Also, special seismic provisions and tapered sections are not included.

- C-Shapes: Only sections with compact webs and flanges are considered in the design checks. All sections of the current AISC tables consider only C-shapes with compact webs and flanges.

- Rectangular HSS: Lateral torsional buckling is checked per section F7.4, however this section only applies to strong axis bending.

- Tees and Angles: The program does not address the rare case where Lateral Torsional (or Flexural Torsional) Buckling occurs for WT’s and double angles bent about their weak axis. Therefore, only yielding is checked for weak axis bending.

- Single angles in compression are not checked for Section E4 because no standard single angle shapes have a slenderness (b/t) > 20. They are also not checked for Section E5 as there is insufficient information regarding the connections and usage of the members.